TECHNICAL DATA

SAINATEC TYPE : ST-YS

SERVICES

Steam, water, oil or gas where protection from foreign matter in a pipeline is required.

MATERIAL

Body/ Housing: Carbon steel – Cast iron – Ductil Iron – stainless steel

PRESSURE RATING

ANSI 150,300,600,900

PN16-100

SIZES

5/8” to 24” (DN15 to DN600)

FLANGE RATING

ANSI B16.5 Raised face

DIN 2533 -DIN 2543 -DIN 2544 -DIN 2545 (Available on request)

TEMPERATURE RANGE

20 TO 100 °C Larger Temperature Range is available upon request

TEST & DESIGN

SAINATEC Fabricated \\\”Y\\\” Strainers can be designed,manufactured and tested in accordance with the requirements of ANSI B31.1, ANSI B31.3, ANSI B31.4, ANSI B31.8 and also ASME Section VIII

BASKETS

Standard baskets are 316 stainless steel and are spot welded for maximum strength. Different size perforations and meshes are available in stainless steel, monel, and brass to meet specific media requirements

Mesh Size : various sizes – please refer to mesh sizes table

APPLICATIONS

For steam, a Y-type strainer is the usual standard and is almost universally used. Its body has a compact cylindrical shape that is very strong and can handle high pressures. It is literally a pressure vessel, and it is not uncommon for Y-type strainers to be able to handle pressures of up to 400 bar g. The use of strainers at these pressures is however complicated by the high temperatures associated with steam at this pressure; and subsequently exotic materials such as chrome molybdenum steel have to be used.

Although there are exceptions, size for size, Y-type strainers have a lower dirt holding capacity than basket strainers, which means that they require more frequent cleaning. On steam systems, this is generally not a problem, except where high levels of rust are present, or immediately after commissioning when large amounts of debris can be introduced. On applications where significant amounts of debris are expected, a blowdown valve can usually be fitted in the strainer cap, which enables the strainer to use the pressure of the steam to be cleaned, and without having to shut down the plant.

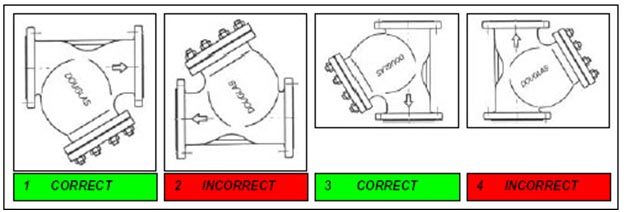

Y-type strainers in horizontal steam or gas lines should be installed so that the pocket is in the horizontal plane . This stops water collecting in the pocket, helping to prevent water droplets being carried over, which can cause erosion and affect heat transfer processes.

On liquid systems however, the pocket should point vertically downwards, this ensures that the removed debris is not drawn back into the upstream pipework during low flow conditions